Quartz and Ceramic Coatings

Quartz (glass) and Nano ceramic coatings for total surface protection

“Surface Science”, is the exploration and exploitation of various phenomena at the intersection of different phases of materials.

In this particular instance of Exterior and Painted surface protection, it is the beneficial ability to allow transfer of particles from one surface to the other so that a Nano (a nanometre is one millionth of a millimetre) coating becomes inseparable from the surface it is applied to.

Automotive Nano-coatings chemically and physically “bond” to the surface, however, dependent on the specific formula and ingredients, the longevity of these coatings can differ. Providing a specific cleaning and maintenance regime is adhered to, these coatings can last anywhere between 2 and 10 years. Quartz coatings chemically bond to the surface and removal can only be done by machine with grit paper

What’s the difference between a quartz (glass) coating and a ceramic coating?

The simple answer is the chemical make-up of the product, what it can be applied to and its durability.

They are both coatings that are applied to a surface to protect it but their chemical constituents are different.

Quartz coatings can be applied to a variety of surfaces for example, painted panels, metal surfaces, plastics, chrome, rubbers, badges, wheels etc. Due to Quartz coatings high melting point, as it chemically bonds to the surface it will not soften unlike a traditional wax or polish which can be easily removed.

A Ceramic coating (just like a quartz coating) chemically bonds with the surface it’s applied to but is designed to be applied to a vehicle’s factory painted panels (bodywork) creating a layer of protection.

Both types of coating create a permanent (or semi-permanent) bond with a vehicle’s a vehicle’s surface, meaning that it does not wash away or break down and does not require repeated application every few months unlike a wax or polish.

Quartz or ceramic coating adds additional protection to a car’s exterior and helps keep it looking like new with comparatively minimal maintenance.

Protection from uv damage/oxidisation/fading

Exposure to the sun can result in paint oxidising/fading, resulting in dulled and faded paint. Quartz and Ceramic coatings have UV filters protecting a vehicle’s paint from the sun’s rays.

By creating a chemically resistant surface, a quartz or ceramic coating will keep a vehicle’s paint protected from various contaminants. The outcome is that paintwork will be more resistant to staining and etching (e.g. from *bird lime and Acid/Alkaline rain). *provided the contaminant is removed reasonably promptly.

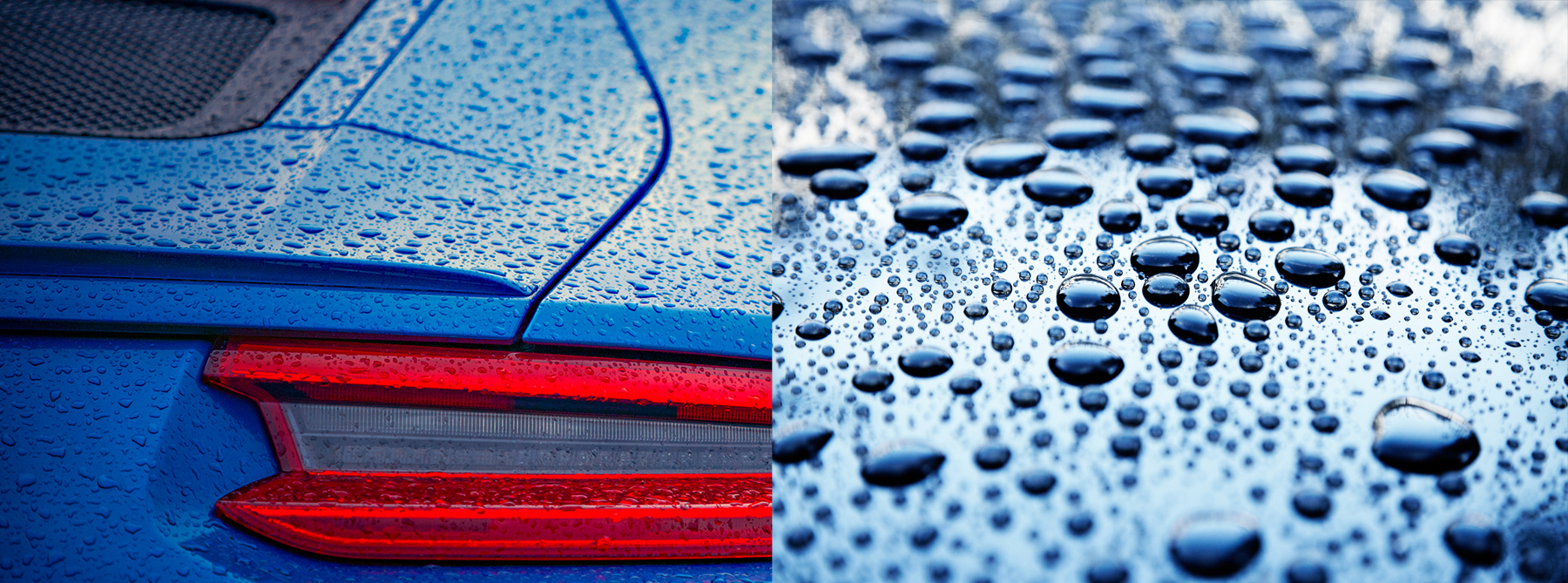

Both quartz and ceramic coatings are hydrophobic, which means they repel water (think of the “Lotus Leaf Effect”). Water will bead on the surface and slide off more easily. Mud, dirt and grime will also not stick to the surface and be easily removed. Another benefit is that there is less drying time as the vehicles surface has much less water clinging to it, reducing water spots

A deeper shine

A quartz or ceramic coating enhances the reflective properties of your car’s paint and clear coat, adding extra depth and clarity to paintwork.

Quartz and ceramic coatings enhance the reflective properties of your car’s paint and clear coat, adding extra depth of gloss and clarity to paintwork.

Scratch protection

Quartz or ceramic coating is up to 3 times harder than your factory paint and lacquer, when the coating bonds to this surface it provides a greater protection from scratches and marring. This does not mean “no more scratches” – it simply means a greater level of protection from scratches than an unprotected lacquered surface